産品簡(jiǎn)介:

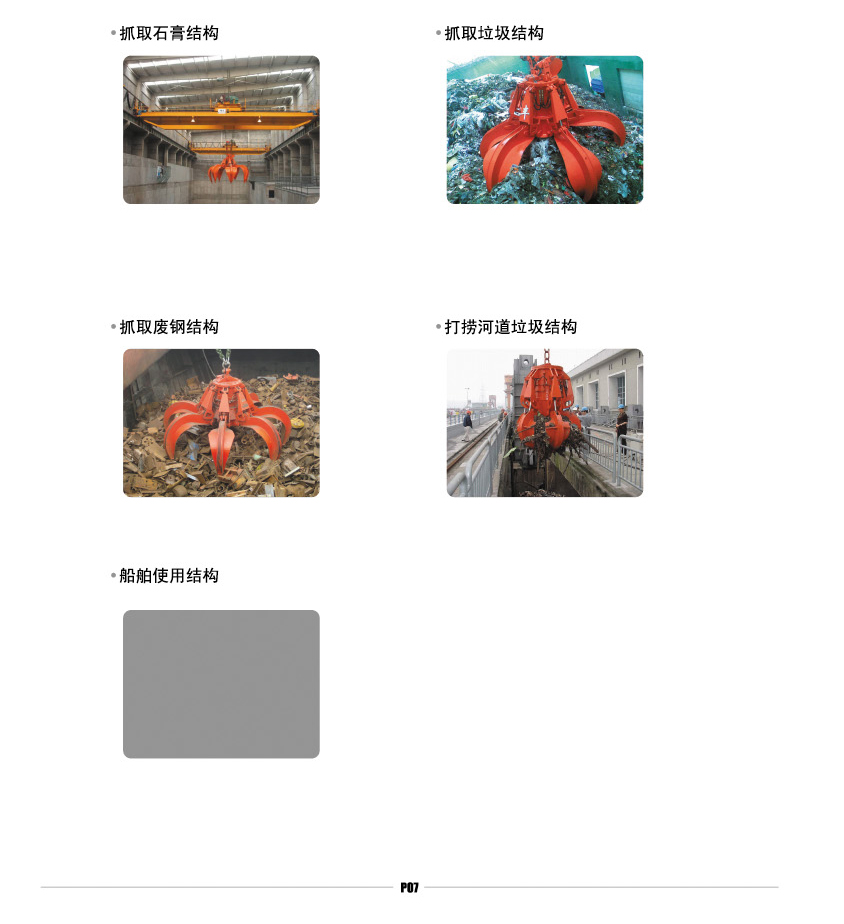

electro hydraulic grab is a kind of grab with its own hydraulic system such as motor and hydraulic pump, which is driven by external power supply to realize opening and closing. the grab depends on the forward and reverse rotation of the motor or the hydraulic directional valve to control the opening and closing of the grab. electro hydraulic bulk cargo grab is an effective tool for handling bulk cargo such as yellow sand, coal, mineral powder, ore and cement in various harsh environments. the grab is equipped with a hydraulic system, and the main components of the hydraulic system, such as valve group, seals, valve blocks, etc., are european and american brands. the hydraulic pump adopts constant power pump and hydraulic servo system. the system pressure change can effectively control the output of the pump. when the maximum pressure is reached, the flow of the pump is very low, which greatly reduces the overflow, reduces energy consumption, and reduces the oil temperature, so as to use long-time continuous work and greatly improve the production efficiency. the grab has simple structure and convenient operation, and can work in various harsh environments. the unique jaw curve is particularly conducive to the loading and unloading of various bulk cargoes. the upper part of the grab is equipped with a cable interface to facilitate the connection with the crane.